| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | NikTech |

| Model Number : | Incoloy 925 |

| Certification : | ISO 9001:2008 |

| Price : | Negotiatable |

| Payment Terms : | L/C,T/T,Western Union,MoneyGram |

| Supply Ability : | 300 Ton per Month |

| Delivery Time : | 2-30days |

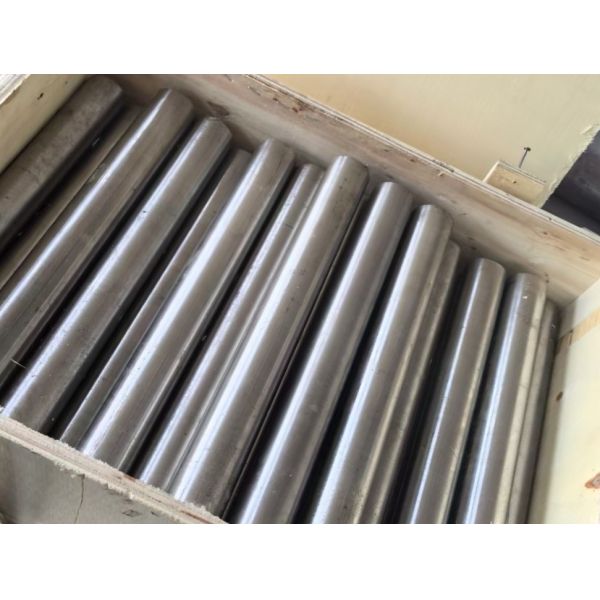

Incoloy 903 Rod: Exceptional Performance in High-Temperature Applications

Incoloy 903, also known as UNS N19903, is a precipitation-hardenable nickel-iron-cobalt alloy renowned for its outstanding combination of mechanical strength, thermal stability, and resistance to thermal expansion. These properties make it an ideal material for components subjected to high temperatures and mechanical stress.

Chemical Composition

Incoloy 903's unique properties arise from its carefully balanced chemical composition:

| Element | Components(%) |

|---|---|

| Nickel (Ni) | 36.0% - 40.0% |

| Cobalt (Co) | 13.0% - 17.0% |

| Niobium (Nb) | 2.40% - 3.50% |

| Titanium (Ti) | 1.00% - 1.85% |

| Aluminum (Al) | 0.30% - 1.15% |

| Iron (Fe) | Balance |

The balance of the composition is predominantly iron, with minimal quantities of other elements.

Mechanical Properties

Incoloy 903 maintains high mechanical strength across a wide temperature range:

Tensile Strength (Precipitation Hardened): Approximately 1310 MPa (190,000 psi)

Yield Strength (0.2% Offset, Precipitation Hardened): Around 1100 MPa (160,000 psi)

Elongation at Break (Precipitation Hardened): 14%

Modulus of Elasticity (at 0°C/32°F): 146.8 GPa (21,290 ksi)

Physical Properties

Key physical characteristics of Incoloy 903 include:

Density: 8.25 g/cm³ (0.298 lb/in³)

Melting Range: 1318°C - 1393°C (2405°F - 2539°F)

Curie Temperature: 416°C - 471°C (780°F - 880°F)

Applications

The unique properties of Incoloy 903 make it suitable for various demanding applications, including:

Rocket-engine thrust chambers

Steam-turbine bolts

Springs

Gage blocks

Ordnance hardware

Frequently Asked Questions (FAQs)

Q1: What industries benefit from Incoloy 903 rods?

Incoloy 903 rods are extensively used in aerospace and power generation industries, particularly for components requiring high strength and stability at elevated temperatures.

Q2: How does Incoloy 903 compare to other superalloys?

Compared to other superalloys, Incoloy 903 offers a unique combination of low thermal expansion and high strength, making it particularly suitable for applications where dimensional stability is critical under thermal cycling conditions.

Q3: What are the heat treatment recommendations for Incoloy 903?

The recommended heat treatment for Incoloy 903 involves solution annealing followed by air cooling or rapid quenching, depending on the desired microstructure and mechanical properties.

For more detailed information on Incoloy 903, including machining and welding considerations, please refer to the datasheet provided by Special Metals.

|