| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Price : | Negotiatable |

| Payment Terms : | L/C,T/T,Western Union |

| Supply Ability : | 300 Ton per Month |

| Delivery Time : | 2-30days |

| Brand Name : | NikTech |

| Certification : | ISO 9001:2008 |

| Model Number : | Cr20Ni80 |

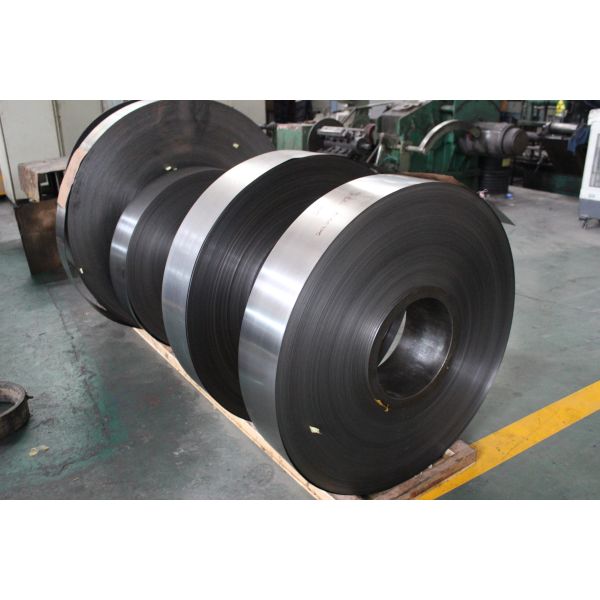

Cr20Ni80 resistance strip is a high-performance nickel-chromium alloy (80% nickel, 20% chromium) designed for demanding high-temperature applications requiring superior oxidation resistance, mechanical durability, and stable electrical resistivity. Renowned for its ability to withstand temperatures up to 1,200°C (2,192°F), this alloy forms a protective chromium oxide (Cr₂O₃) layer that prevents scaling and degradation in oxidizing atmospheres. Its low iron content (<1%) and controlled trace elements (e.g., manganese, silicon) ensure minimal embrittlement and long-term reliability in cyclic heating environments such as industrial furnaces, electric heaters, and aerospace components.

Certified to ASTM B344 and GB/T 1234 standards, Cr20Ni80 strip achieves a tensile strength of 650–850 MPa and elongation ≥20%, outperforming conventional Fe-Cr-Al alloys in high-temperature stability. With an electrical resistivity of 1.09 µΩ·m and a low temperature coefficient of resistance (TCR), it delivers consistent energy efficiency in air, vacuum, or inert gas environments, making it ideal for precision heating applications in sectors like energy production, chemical processing, and consumer electronics.

| Property | Value | Standard |

|---|---|---|

| Chemical Composition | Ni: 75–80%, Cr: 19–21%, Fe: ≤1.0% | ASTM B344, GB/T 1234 |

| Mn: ≤0.6%, Si: ≤1.0%, C: ≤0.08% | DIN 17470 | |

| Mechanical Properties | Tensile Strength: 650–850 MPa | ASTM E8 |

| Elongation: ≥20% | ||

| Physical Parameters | Density: 8.4 g/cm³ | ISO 6892 |

| Melting Point: 1,400°C | ||

| Electrical Resistivity: 1.09 µΩ·m |

Industrial Furnaces: Heating elements for annealing, sintering, and heat treatment processes.

Energy Sector: Electric boilers, nuclear reactor components, and solar thermal systems.

Consumer Appliances: Oven coils, toasters, and hair straighteners.

Aerospace: Ignition systems and turbine blade heating elements.

Automotive: Glow plugs, exhaust gas recirculation (EGR) heaters.

Q1: What is the maximum continuous operating temperature for

Cr20Ni80 strip?

A: 1,200°C in oxidizing atmospheres and 1,050°C in reducing or

vacuum environments.

Q2: Can Cr20Ni80 withstand sulfur-rich environments?

A: Limited resistance. For sulfur exposure above 800°C, consider

alloys with higher chromium or molybdenum content.

Q3: Is pre-oxidation necessary for optimal performance?

A: Optional but recommended. Heat-treat at 900–1,000°C for 1 hour

to enhance oxide layer adhesion.

|